BMW Group Expands Global Network of High-Voltage Battery Production for Neue Klasse

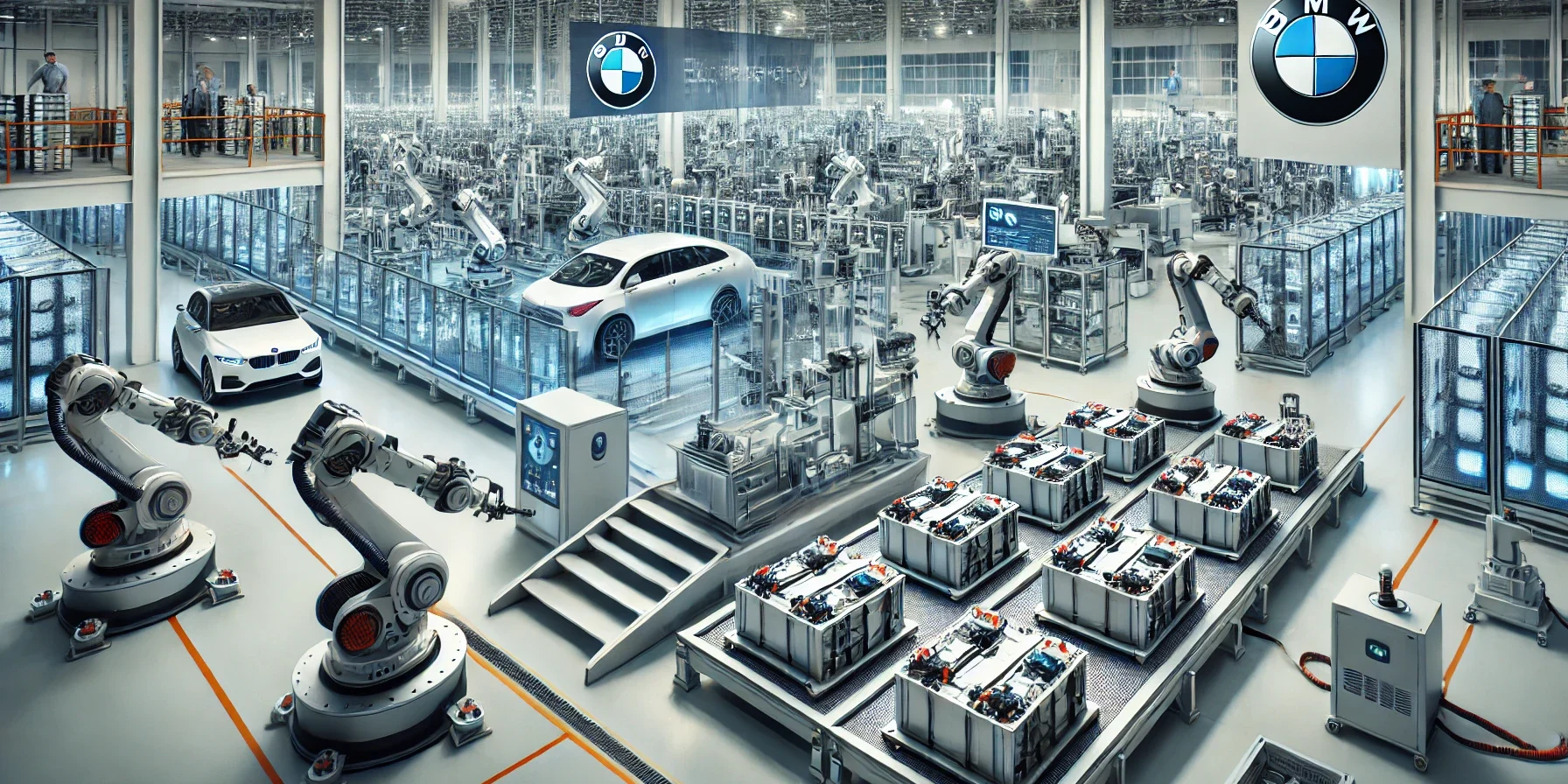

The BMW Group is set to usher in a new era of fully electric driving with its Neue Klasse, underpinned by a significant expansion of its high-voltage battery production network. Milan Nedeljković, Board Member for Production at BMW AG, announced: “We are establishing five facilities across three continents to produce our sixth-generation high-voltage batteries.” This ambitious strategy, dubbed “local for local,” aims to closely link battery production with vehicle assembly.

Markus Fallböhmer, Senior Vice President of Battery Production at BMW AG, emphasizes that the close connection between battery and vehicle production is a key element of the company’s strategy. This approach allows BMW Group to increase the resilience of its production against potential disruptions and reduce the carbon footprint of car production through shorter transportation routes.

New Production Facilities:

- Irlbach-Straßkirchen, Germany: Construction began in June 2024, with the first pillar of the production hall erected in late June, after obtaining permission in April. The production building is scheduled to be enclosed with facade and roof by the end of the year. This decision followed a clear majority vote in favor of BMW Group’s presence in a September 2023 referendum.

- Debrecen, Hungary: Production starts in 2025, parallel with the assembly of the first Neue Klasse vehicles. The training center has been operational since autumn 2023, and the communication center since February 2024. A large number of employees are already working at the site, with the production team preparing at various locations across the BMW Group production network.

- Shenyang, China: The production hall was completed in November 2023 after just 21 months of construction. Machinery installation has been ongoing since March 2024, with Neue Klasse production set to begin in 2026. BMW Group has also established its largest R&D network outside Germany here, with facilities in Beijing, Shanghai, Shenyang, and Nanjing.

- San Luis Potosí, Mexico: Construction started in May 2024, with production planned from 2027. The new high-voltage battery assembly plant will comprise more than 80,000 square metres of production space. The bodyshop is set to grow to over 90,000 square metres, while vehicle assembly and logistics spaces will expand by nearly 10,000 square metres.

- Woodruff, USA: Under construction, it will supply the Spartanburg plant from 2026. The site will cover about 93 hectares and create over 300 new jobs. It will consist of a technology building, ancillary structures, an energy centre, a staff restaurant, a fire department, and a Talent Campus.

Technological Innovations:

The Neue Klasse will be the first to incorporate all-new cylindrical cells, representing a technological leap by BMW Group. These cells offer significantly improved energy density, shorter charging times, and greater range. These advanced batteries will be assembled in new facilities located as close as possible to car factories, adhering to the “local for local” principle.

Sustainability Initiatives:

In San Luis Potosí, an expansion of photovoltaic systems is planned, aiming to double the power generated from photovoltaics and cover over 20% of the plant’s electricity demand. This aligns with BMW Group’s commitment to sustainable production methods and reducing its environmental impact.

Competence Centers:

BMW Group concentrates its battery expertise in two key locations:

- Cell Manufacturing Competence Centre (CMCC) in Parsdorf: This facility scales up the best product prototypes for series production.

- Battery Cell Competence Centre (BCCC) in Munich: Here, development work on battery technologies is carried out.

These centers uniquely interlink product and process through close collaboration across divisions, including Development, Purchasing, and Production. Additional pre-series plants and pilot lines for future high-voltage batteries are operated in Munich and the nearby towns of Parsdorf and Hallbergmoos.

This comprehensive high-voltage battery production strategy underscores BMW Group’s commitment to electrification and sustainable production. By investing in local production facilities and cutting-edge technology, the company is positioning itself as a leader in the global transformation of the automotive industry, combining technological innovations with a responsible approach to production and local community development.